The competitiveness of small and medium-sized manufacturing companies is based on product innovation and time-to-market reduction. The introduction in the market of new products that are increasingly competitive requires the adoption of a series of methodologies (TCT, Time Compression Technologies), whose integration allows to obtain significant reductions in planning, design and engineering times. Reverse Engineering (RE) is one of the tools supporting companies to tackle and overcome these challenges. This technology arises from the need to quickly realize prototypes (virtual and real) useful for the aesthetic-functional evaluation of the product being studied.

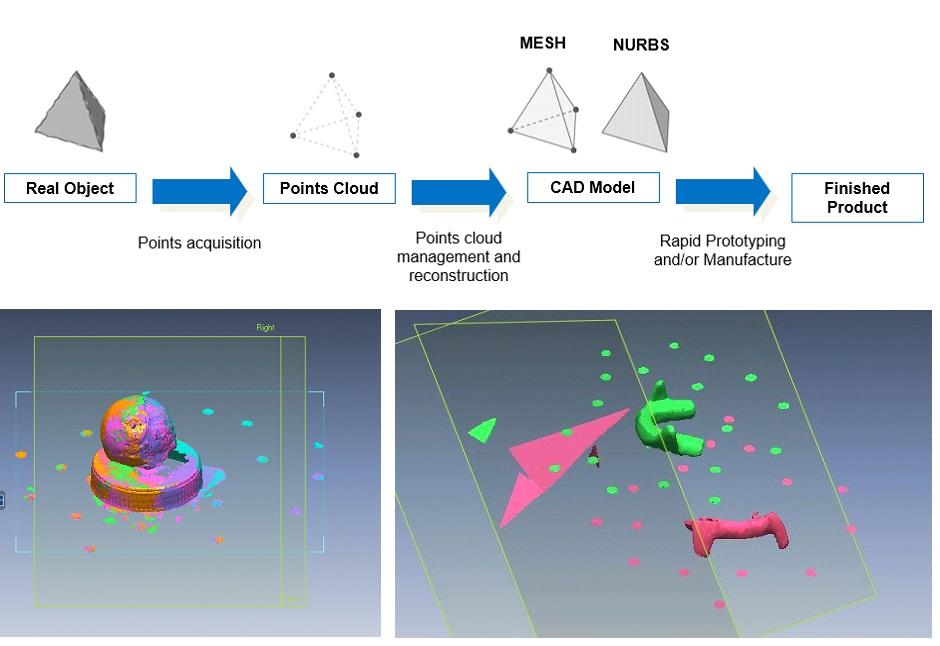

RE allows the reconstruction of a digital model starting from a real object or from a part of it. The method starts from the digitization and the measurement of the coordinates of the points belonging to the surface of an object and continues with the translation of the acquired points cloud in a CAD model, through different techniques chosen according to its geometry. This methodology is called Reverse because it is both conceptually and operationally opposed to traditional engineering systems that start from a CAD model to produce a real object.

Not only industrial design uses RE techniques, but also the automotive industry, the archaeological sector, the medical sector, the field of recovery of buildings belonging to the artistic and architectural heritage, the animation industry and the virtual world. RE is used in various situations that can be found even in very different fields:

Research activities that exploit RE technologies, within this department, are mainly focused in the fields of:

Reverse Engineering laboratory