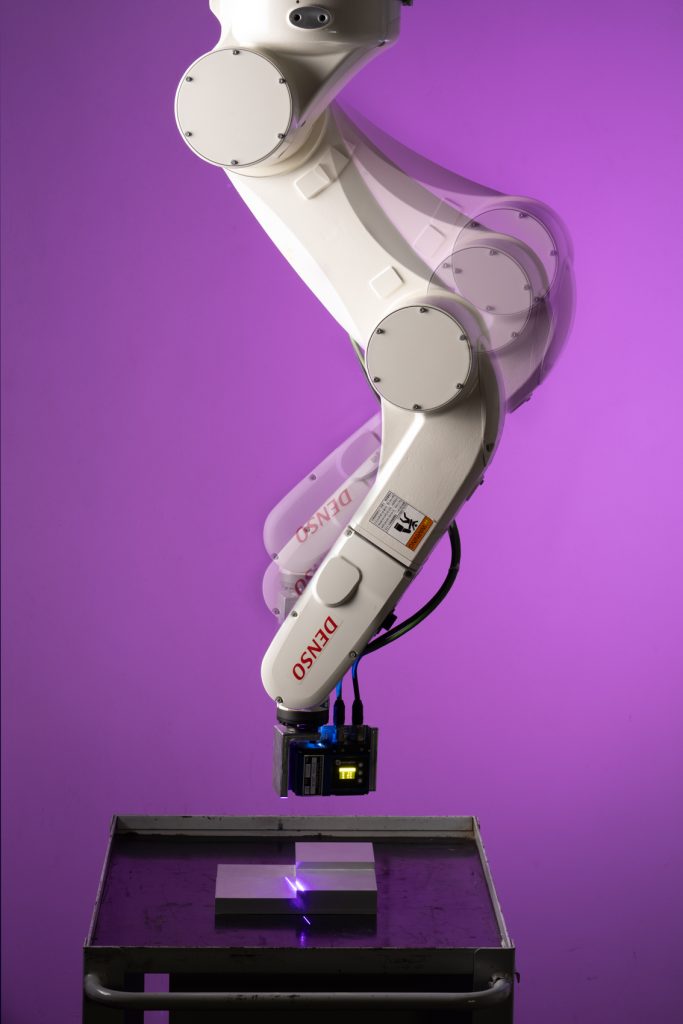

Numerous research activities implement non-destructive quality control and diagnostic systems in the industrial field as part of collaborations with partner companies and regional, national, or European projects. Multiple optical techniques are applied in industry, such as matrix and linear cameras, high-speed cameras, hyperspectral cameras, telecentric vision systems, and lidar for dimensional measurements, crack identification, surface defects, or material characterization. Vision-based systems such as laser line triangulation profilometers are integrated into production lines for non-contact dimensional control of industrial components with measurement ranges varying from micrometers to meters depending on the application (electronics, automotive, metallurgy, steel industry, etc.). The use of software algorithms such as pattern matching, edge detection, blob analysis, and point-cloud analysis, combined with the hardware development of custom systems dedicated to hostile industrial environments, allows for early defect identification and preventive diagnosis. As part of our research activities, we develop applications up to TRL 7, where complete automated quality control stations are integrated in production line and connected to digital platforms. Other areas of application include manufacturing, aerospace, civil/construction, rail, and electronics.

Prof. Nicola Paone

Tel. +39 071 220 4490

email: n.paone@staff.univpm.it

Prof. Paolo Castellini

Tel. +39 071 220 4441

email: p.castellini@staff.univpm.it

Prof.ssa Milena Martarelli

Tel. +39 071 220 4542

email: m.martarelli@staff.univpm.it