Today, thanks to the advent of new IoT and ICT technologies introduced with the advent of Industra 4.0, manufacturing industries can easily collect a large amount of information about their products and processes. Such information, thanks to the new technologies of artificial intelligence of big data analytics, can be used profitably both to improve the quality of the products/processes themselves, and to enhance the know-how of companies, and generate new value, by implementing servitization processes.

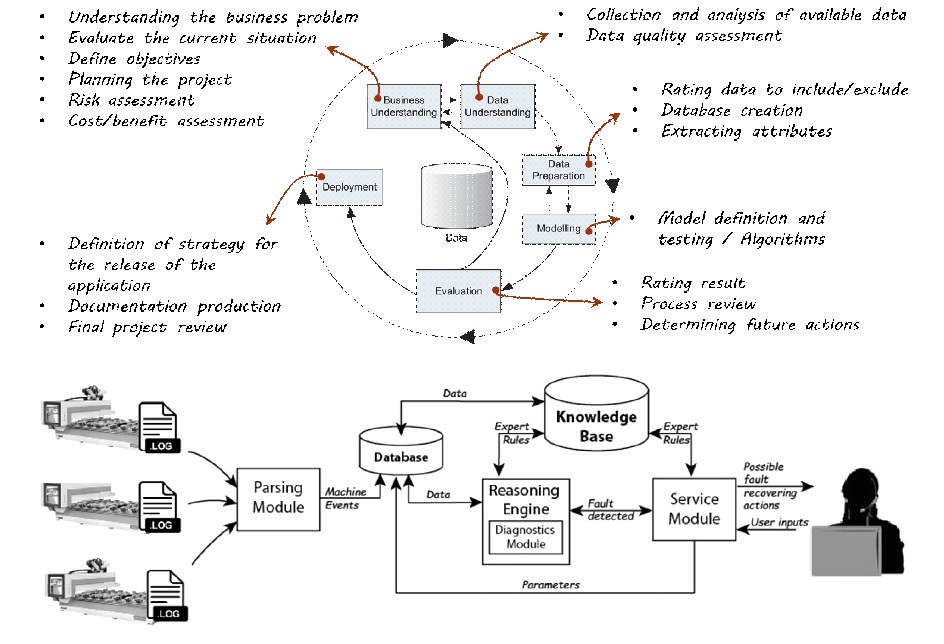

In this context, the research activity focuses on the study and definition of methods and tools to guide the development and implementation of new predictive maintenance services, according to a CRISP (Cross-Industry Standard Process) approach.

The activities are carried out in the Virtual Prototyping and Virtual Reality laboratory