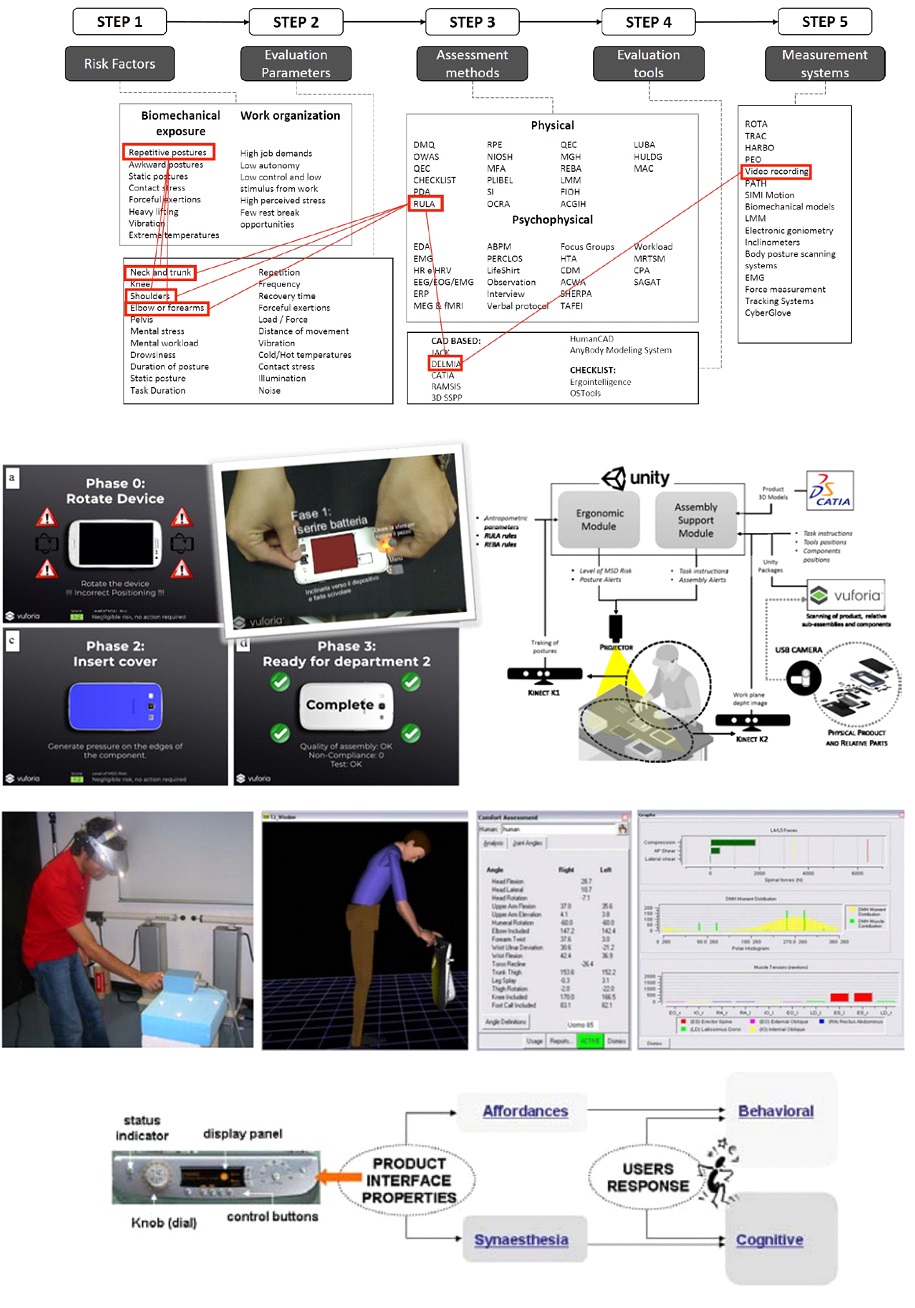

Today, in order to improve their competitiveness, companies must aim at continuous improvement of the quality of their products, services, personnel, processes and environment. Reducing the risk factors for musculoskeletal disorders in workers can reduce expected costs and improve process efficiency, thanks also to the reduction of absenteeism and less frequent interruptions. Traditional approaches are based on monitoring critical issues and introducing optimisation actions. To ensure worker safety and prevent potential risks in order to concretely reduce accidents and other diseases of workers, human factors must be taken into account in the design of the working environment and in the planning of processes. To this end, the use of Virtual Reality (VR) and Augmented Reality (AR) technologies can create immersive and interactive spaces where real users can simulate the actions of workers with a high level of presence and realism, depending on the monitoring and interaction technologies used. However, the determination of which technologies are most suitable to support the design of environments and workstations, as well as the verification and management of acual levels of risk during work, based on the characteristics of the specific application context remains an open point for research. In this context, the research activity focuses mainly on the following objectives:

In recent years the use of virtual prototyping (VP) has increased in the product development process. The understanding of the advantages of VP, especially in human-machine interaction design, has initialised efforts made by companies. In addition, virtual prototyping technologies (software and hardware) are easily available and the prices have come down. Nevertheless, there is a need for a better understanding of what VP really is, how it is used, how it changes the production processes and how it differs from physical prototyping:

The activities are carried out in the Virtual Prototyping and Virtual Reality laboratory