A key factor related to production process is the resource consumption, at first energetic ones. Production processes are one of the systems included into European Strategies 2030. The minimization of CO2 emissions related to production of goods is one of the main factors considered. In this regard, methods for modelling, analysis and simulation of the energy consumption, environmental impact calculation and energy benchmarking have been widely analyzed by the literature. On the other hand, most of existing methods and tools for energy/resource assessment focus on a quantitative analysis of consumptions with the aim to increase energy awareness rather than on the analysis of efficiency. The innovation that actually lacks is to systematize the analysis phase with data available from Smart Factory. The object is to derive a smart system able to identify the problem and to implement improving solutions, in the perspective of continuous improvement of energy performances.

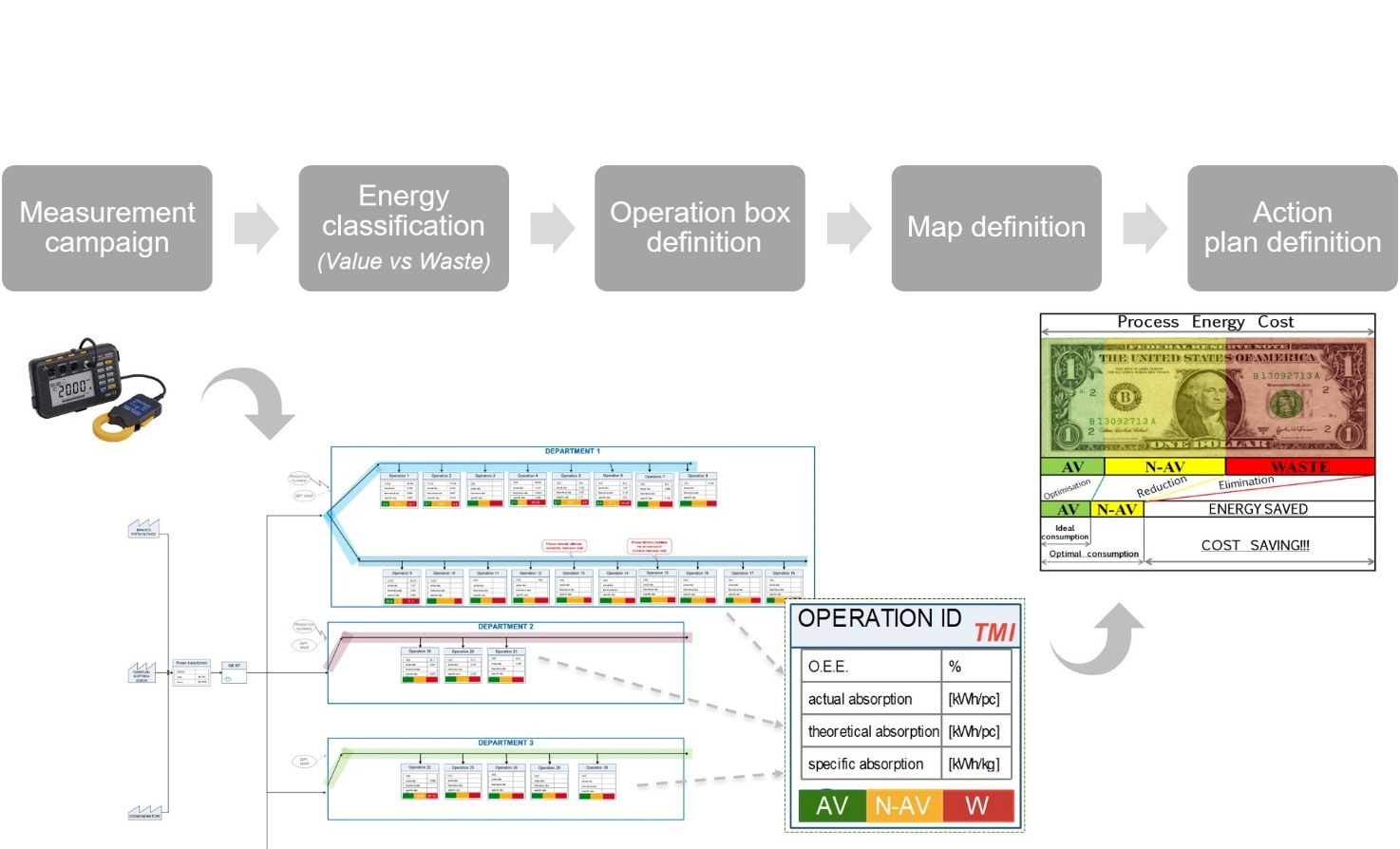

In this context, the research is aimed to support industries both in the data acquisition process in terms of identification of necessary data, suggestion of acquisition means and definition of a proper information flow and in the assessment of energy value flowing in a production system, according to the Energy Value Stream Mapping method (EVSM). The final goal is to increase the sustainability of the processes through identification of energy wastes, aiming at eliminating them. A structured data framework for the energy plant assessment tries to overcome the difficulties related to the inventory phase, which is a time-consuming activity. An efficacious mapping of the current production system allows understanding how consumptions are distributed along the production flow and correlate them with the company asset performances, production planning, and resources management. This is the starting point to identify and characterize the energy flow associated with the production processes, highlighting the “value-added” component, i.e. the minimum energy needed to perform a particular process, the “no added value” component, i.e. the energy that does not add value to the product but which is necessary for the execution of the various activities, and the wasted component, i.e. the energy for which the customer is not willing to pay and which does not contribute to the transformation of the product. Digitizing the line and ad hoc algorithms allow to appropriately allocate all the consumptions across the various activities, to identify the most critical process nodes from the energetic point of view and to define and implement corrective actions (real-time and offline, vertical and horizontal), depending on production, which ensure a more efficient use of resources and the waste reduction.

Virtual Reality and Virtual Prototyping laboratory.