Advanced solutions for industrial automation are designed and developed. Research includes the design of intelligent mechatronic systems, the study of collaborative robots, advanced sensor technology and algorithms for control, artificial vision, and the optimization of production processes.

Technology transfer takes place through collaborations with companies, funded projects, prototype development and patents, as well as technical consulting and training activities. The goal is to bring innovative technologies from the laboratory to the factory, supporting industrial innovation and competitiveness in the region.

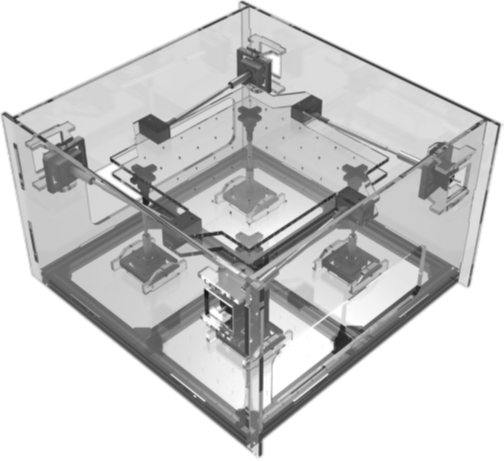

Mock-up of the desk‑size parallel kinematic machine for simulation of seismic events (STRIC/STRIC+ project)

Prof. Massimo Callegari

Tel. +39 071 220 4444

E-mail: m.callegari@staff.univpm.it