The interest in environmental sustainability issues has been increasing in recent years, both from companies’ point of view, through the development of products with low environmental impact, and from the point of view of consumers who are driven to purchase “green” products. The concept of environmental sustainability collects therefore different needs that have as their final objective the reduction of the environmental burden connected to products/processes/services. Some key concepts are: Design for Environment, i.e. the integration of environmental aspects within the product development process (ISO 14006: 2011), and Life Cycle Thinking, i.e. the adoption of a perspective extended to the entire product life.

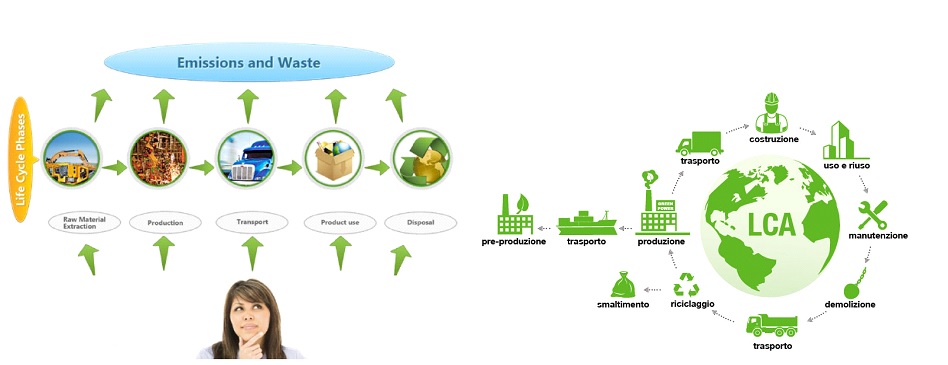

The first step towards the development of products/processes/services with low environmental impact is the evaluation and quantification of their environmental impacts through the application of methodologies and tools of Life Cycle Assessment (LCA). These standardized methodologies and tools (ISO 14040: 2006 and ISO 14044: 2006) allow the product modelling and provide quantitative results expressed through numerous indicators of environmental impact (the most common is KgCO2 equivalent). In particular, the application of these methods and tools allows to:

When the environmental impacts assessment takes place already in the early stages of design, we speak of Eco-design. In this case, the objective is to anticipate the evaluation at the early design stages, to evaluate different design alternatives (e.g. materials, production processes, etc.) that affect the environmental behaviour of the product/process/service. Research activities related to eco-design are focused on:

The group uses commercial LCA tool (Simapro, PRé Sustainability) and has developed prototype software tools in the course of research and project activities. In particular:

The activities are carried out in the Virtual Prototyping laboratory