The vibration measurement laboratory deals with the development and application of measurement techniques and strategies for the vibrational characterization and modal analysis of components applied in the most disparate sectors (from mechanics to biomedics, up to the civil sector and cultural heritage conservation).

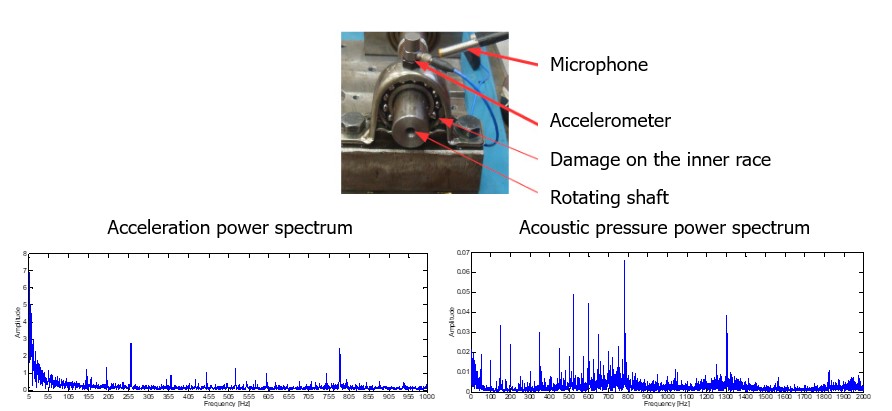

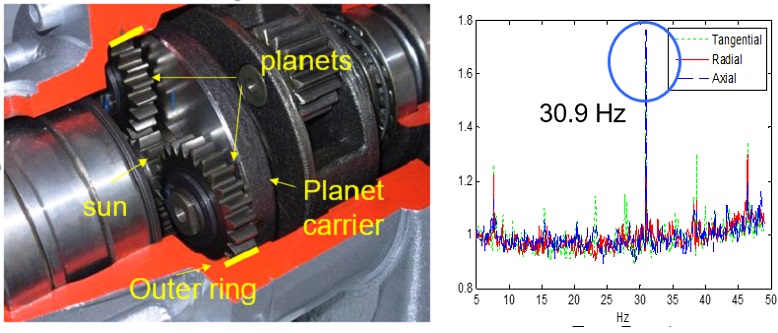

Quality control of rotating machinery

Rolling bearing diagnostics by means of vibro-acoustic analysis based on Empirical Mode Decomposition and Blind Source Separation.

Diagnostics of epicyclic gears based on envelope cepstrum and wavelet denoising.

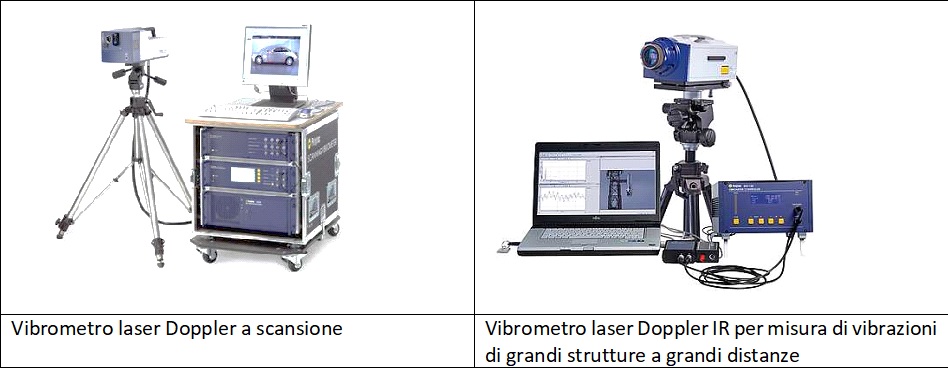

The main measurement techniques used, in addition to traditional sensors, such as accelerometers and load cells, are those related to laser vibrometry technology.

The laboratory has several vibrometers for measuring axial vibration, scanning, in-plane and rotational, in the various versions suitable for industrial, laboratory or field applications.

In this laboratory, original solutions have also been developed, such as tracking vibrometry or continuous scanning, so as to offer performances not available on commercial systems.

Examples of application of the non-contact techniques based on laser Doppler vibrometry are:

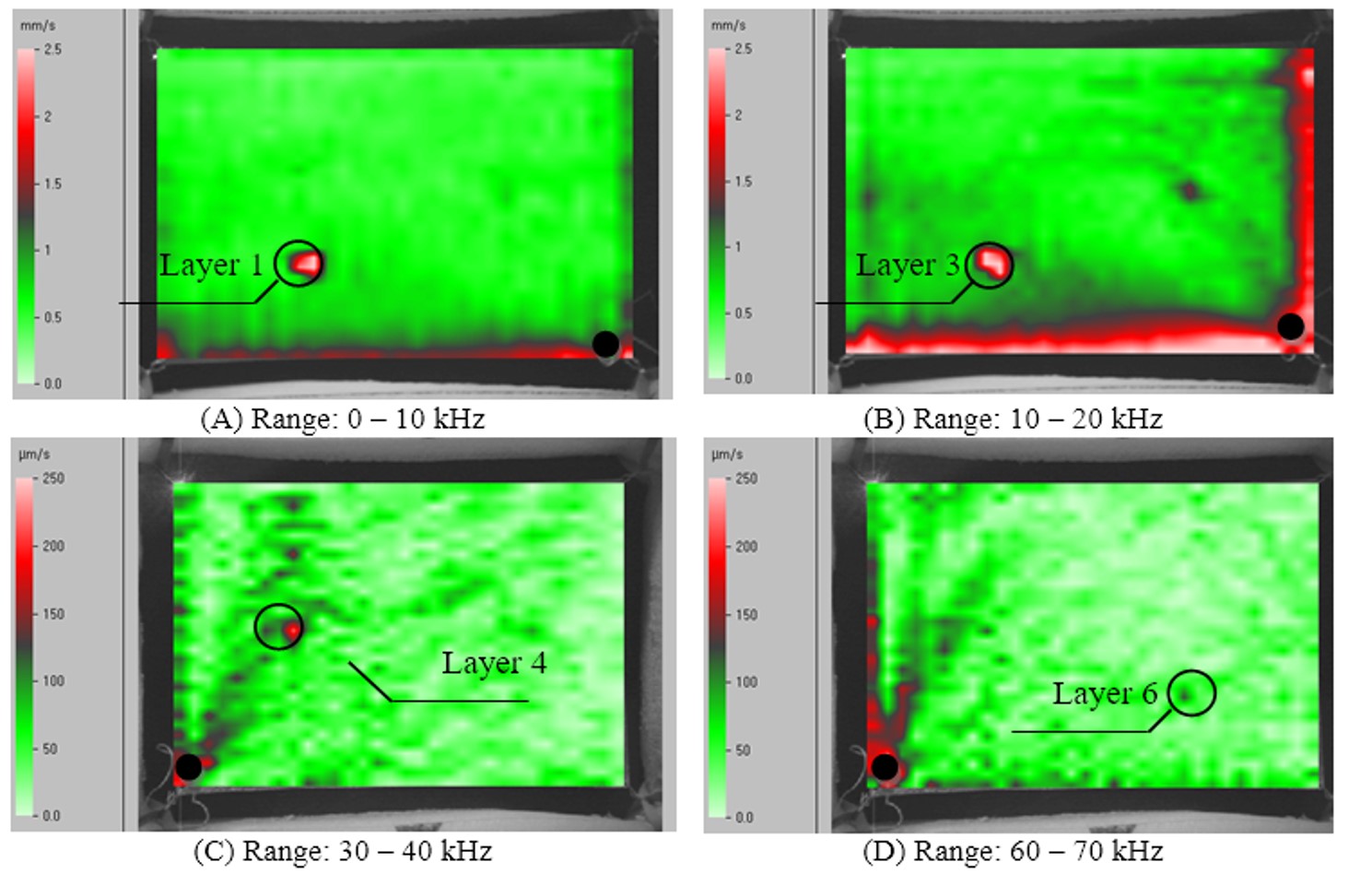

Quality control in aeronautic sector

Delamination diagnostics on components of composite material exploited for the construction of new generation aircrafts fuselage.

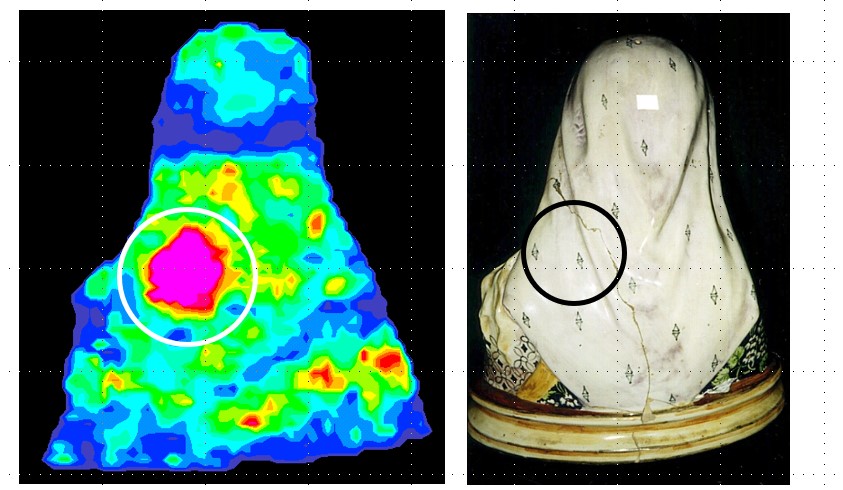

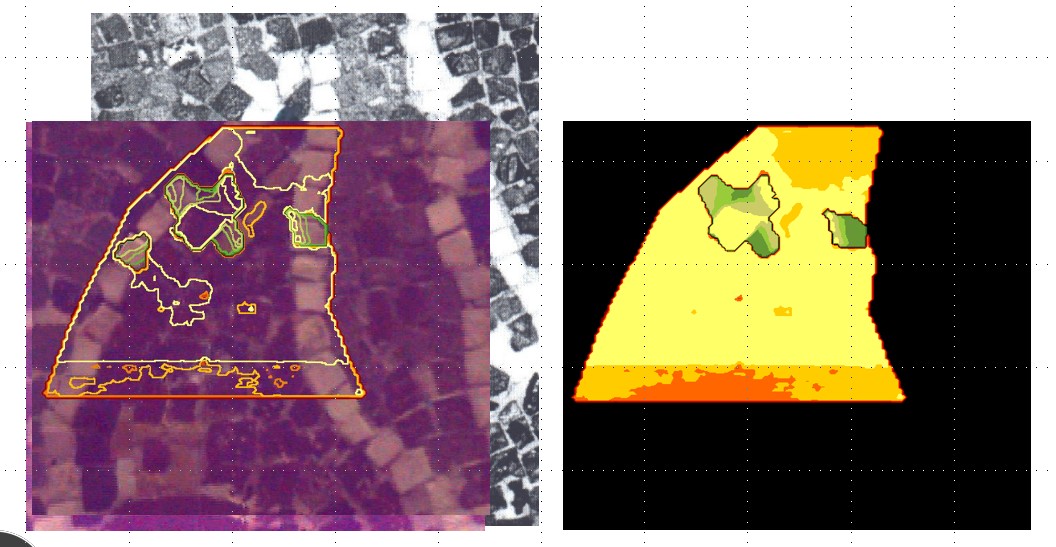

Health monitoring of artworks

Ceramic bust of XIX century

Mosaic

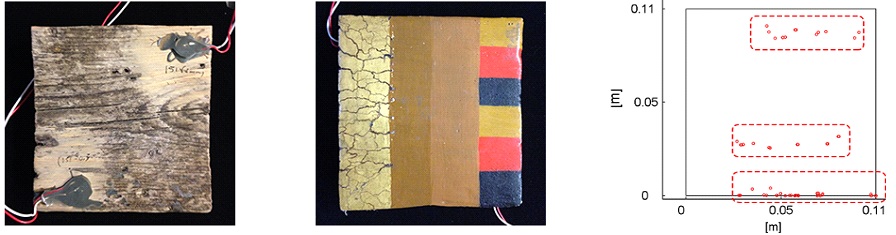

Wooden icons. In this case, processing of data acquired by means of a continuous scanning Doppler laser vibrometer based on wavelet analysis has been used to identify the position of defects associated with coating detachment from the wooden substrate.

Diagnostics of camorcanna vaults (detection of frescoes detachment from the reeds substrate).

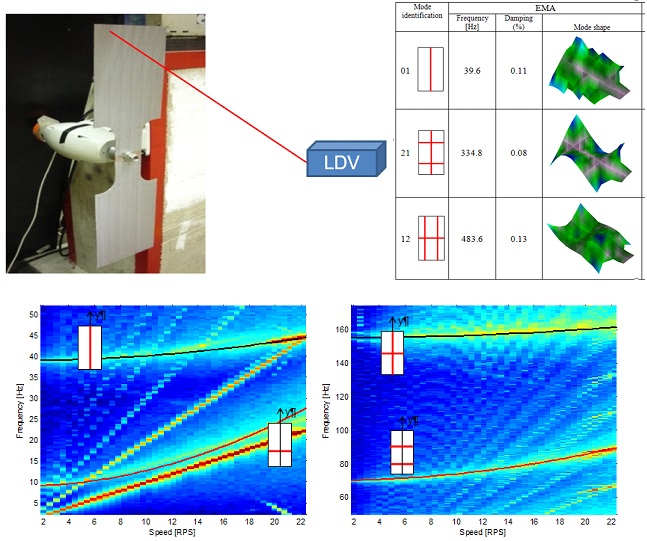

Continuous tracking laser Doppler vibrometry for rotating machinery dynamic characterization

Dynamic characterization of a double blade rotor in rotating conditions.

Light material characterization

Mechanical characterization of loudspeakers materials (paper, rubber). Characterization of the modal parameters by using vibration test data (LDV) and computation of complex modulus of the material by means of a reverse calculation based on an analytical model.