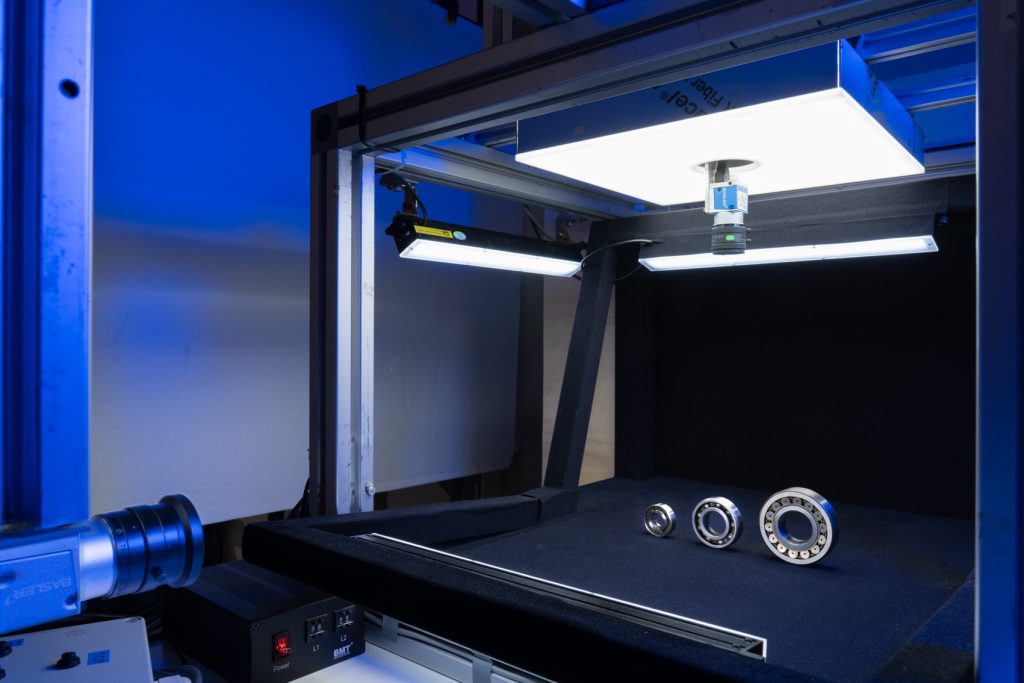

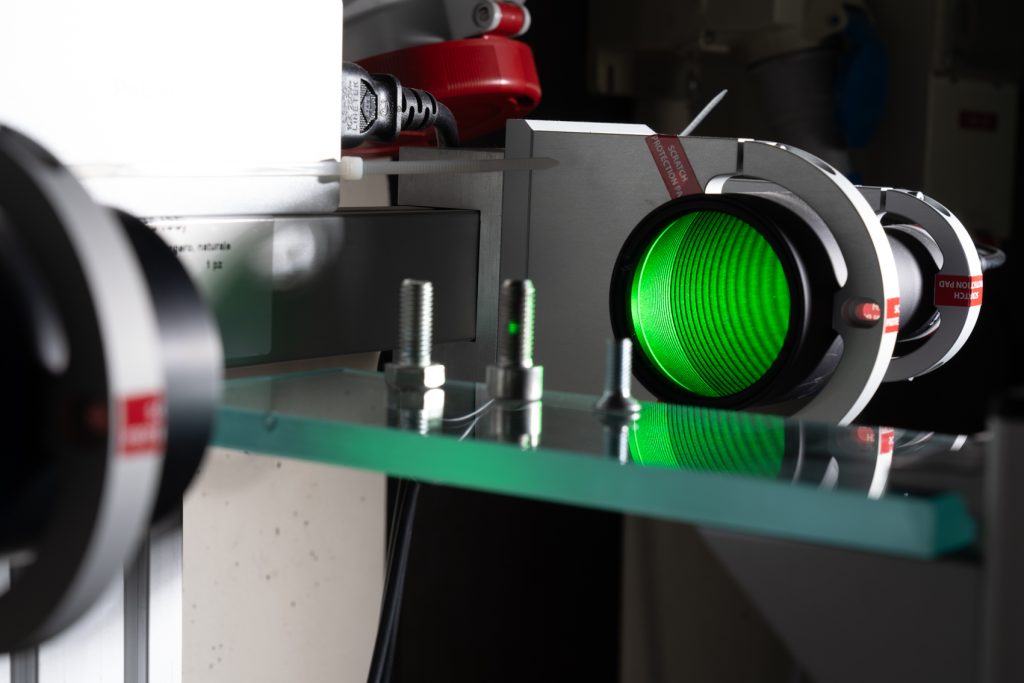

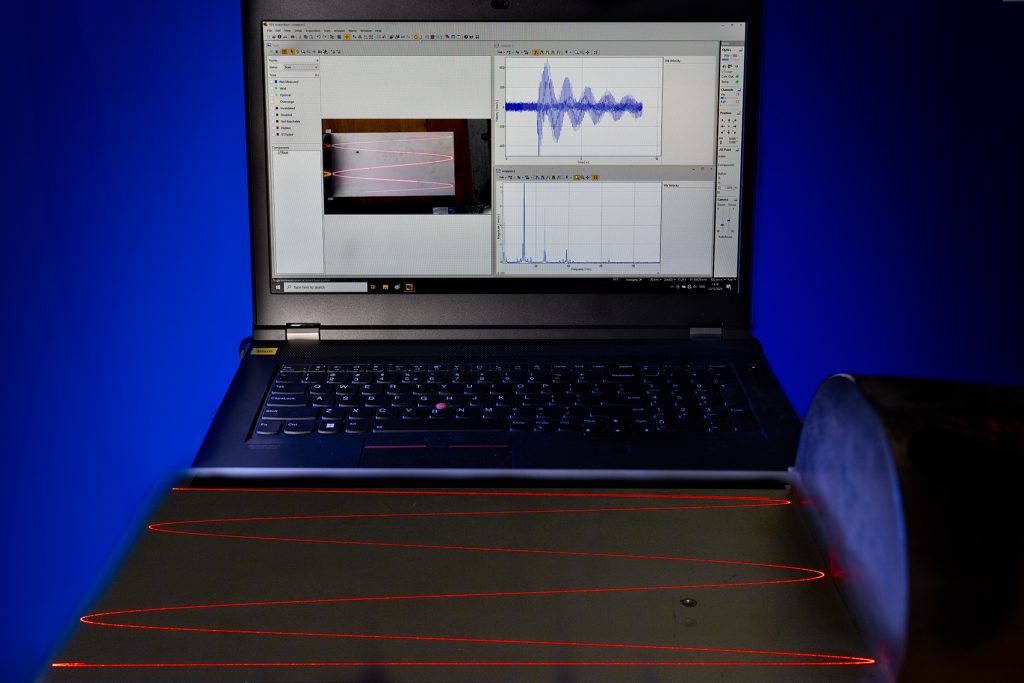

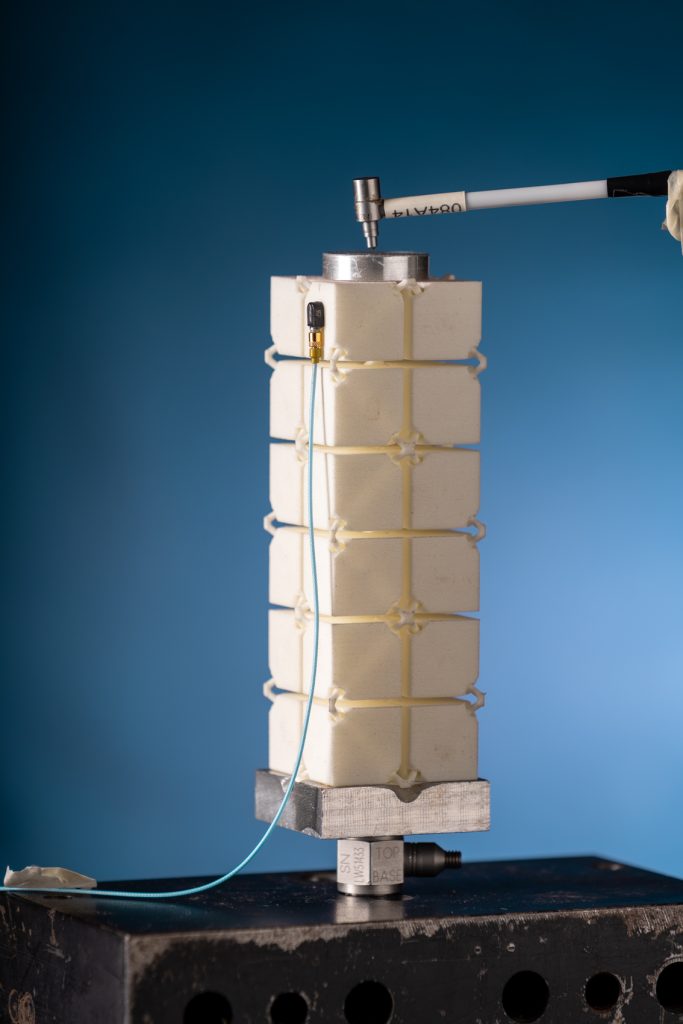

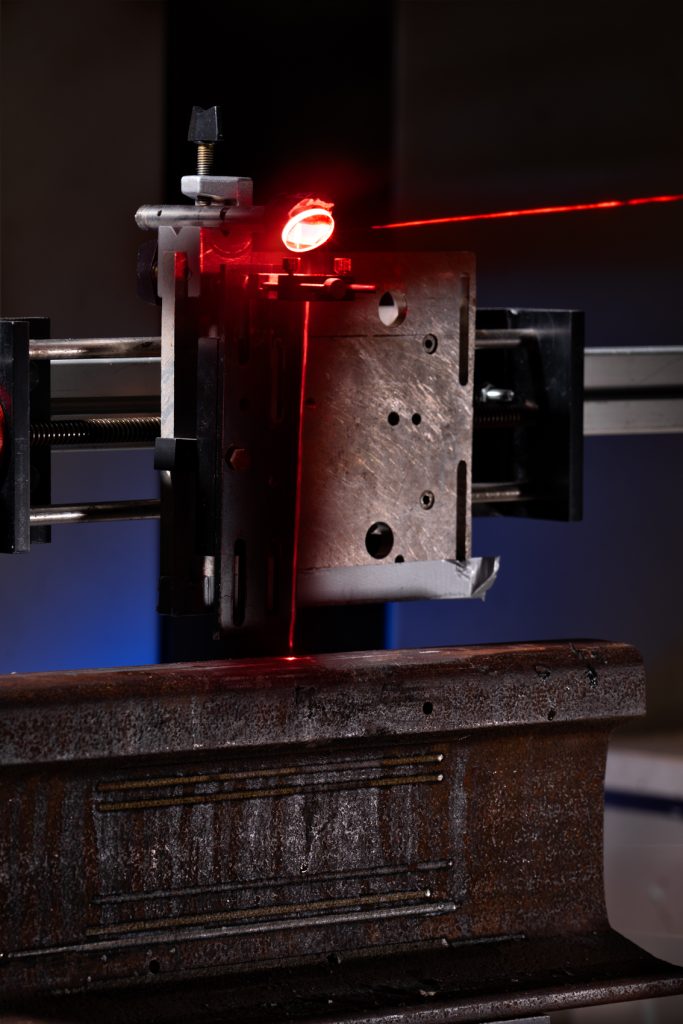

The activity focuses on the development, integration, and industrial application of advanced measurement systems, with a distinctive specialization in non-contact techniques for quality control, process monitoring, and diagnostics. The approach combines optical, acoustic, and thermal instrumentation with advanced algorithms to support the digitization and sustainability of industrial production.

The main methodologies used include:

Applications include manufacturing (automotive, household appliances), aerospace, civil engineering/construction, agriculture, and biomedicine.

Staff

Prof. Gian Marco Revel

Tel. +39 071 220 4518

email: gm.revel@staff.univpm.it

Prof. Nicola Paone

Tel. +39 071 220 4490

email: n.paone@staff.univpm.it

Prof. Paolo Castellini

Tel. +39 071 220 4441

email: p.castellini@staff.univpm.it

Prof.ssa Milena Martarelli

Tel. +39 071 220 4542

email: m.martarelli@staff.univpm.it